Ball valves are widely used in various industrial applications for their ability to regulate and control the flow of liquids and gasses. Ball valves use a rotating ball to open and close the flow of fluid through the valve body. The ball has a hole in the center that allows the fluid to pass through when the valve is open, and when it is rotated to the closed position, the hole is blocked and the flow of fluid is stopped. Read More…

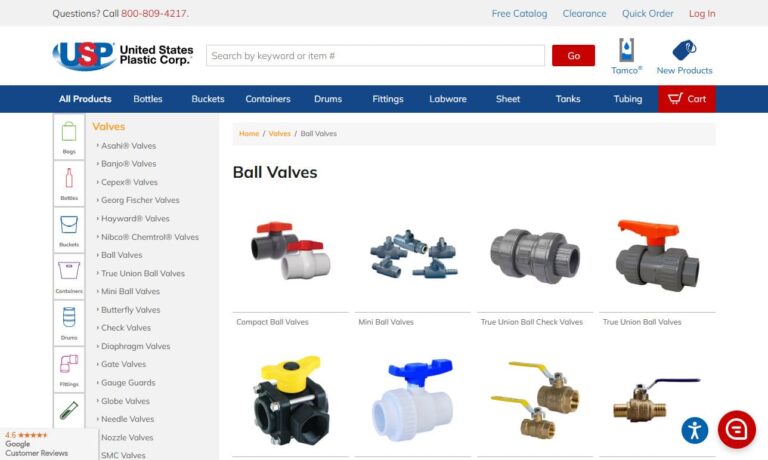

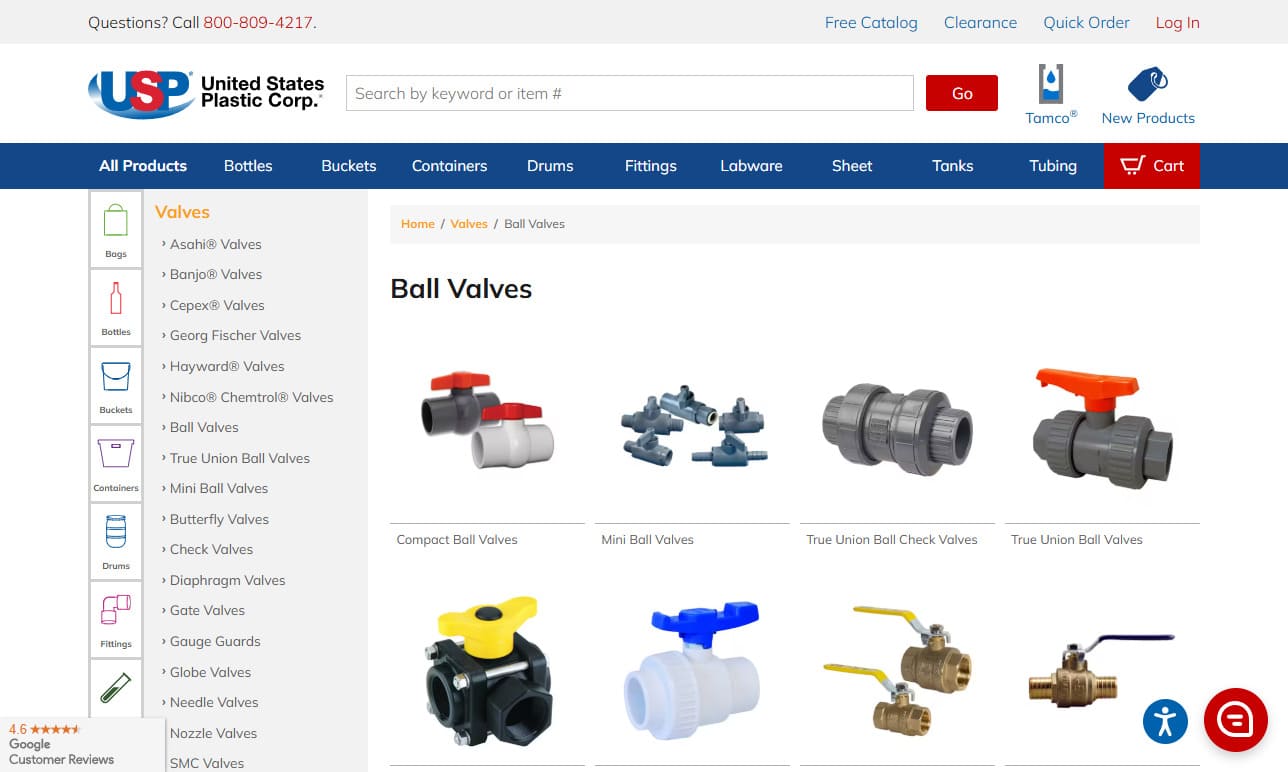

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Valworx offers ball valves in Stainless Steel, Sanitary, Brass and PVC. Our standard quarter-turn ball valves use handles for manual operation. For actuation, some ball valves feature a mounting pad cast into the housing for mounting directly to pneumatic or electric actuators. Actuated ball valve assemblies are typically used for On/Off or modulating control of water, air, oil and other...

C & C Industries offers high-quality threaded brass ball valves through 4" rated to 600# WOG and carbon steel and ductile iron ball valves through 3" rated up to 5000# WOG. In addition, C & C Industries offers a full line of flanged products in both floating and trunnion design.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Brass Ball Valve Manufacturers

Why Brass Is Used for Ball Valves

Brass is a popular material used in the creation of ball valves due to its physical properties. Brass is an alloy made of copper and zinc, which makes it corrosion-resistant, easy to machine, and manufacturable. Corrosion resistance is one of the most important factors when it comes to selecting materials for ball valves. Brass has excellent corrosion resistance, especially in environments that have a high concentration of water or moisture. The zinc component of the brass alloy creates a thin layer of protective oxide, which prevents the valve from corroding. Brass also has excellent resistance to tarnishing, making it ideal for use in decorative applications. In addition, brass has excellent machinability, which means that it is easy to manufacture into intricate shapes and sizes. This makes it a popular choice for manufacturing ball valves in a range of sizes, from small to large.

Considerations Regarding Brass Ball Valves

While brass is a popular choice for creating ball valves, it does have some considerations. One of the biggest considerations regarding brass ball valves is their susceptibility to dezincification. Dezincification is a type of corrosion that occurs in brass when it comes into contact with certain chemicals, such as acids or alkalis. This can cause the brass to become brittle and eventually fail. Another limitation of brass ball valves is their lower maximum operating temperatures compared to other materials. Brass ball valves are suitable for use in temperatures up to around 200°F, after which they may start to deform or crack.

Benefits of Brass Ball Valves

Despite these limitations, brass ball valves offer several benefits. They are highly durable and long-lasting, making them ideal for use in applications where frequent maintenance is not feasible. Brass ball valves also have a low friction coefficient, which makes them easy to operate and helps to prevent wear and tear. Additionally, brass ball valves are versatile and can be used in a wide range of applications across various industries.

Case Studies Proving These Benefits

There are several case studies available that demonstrate the durability, ease of operation, and versatility of brass ball valves. Here are a few examples:

Marine Industry

A case study from a marine engineering company demonstrated the durability of brass ball valves in harsh saltwater environments. The company found that brass ball valves outperformed other types of valves in terms of reliability, durability, and ease of maintenance.

Oil and Gas Industry

In a case study conducted by an oil and gas company, brass ball valves were found to be versatile and suitable for a wide range of applications, including high-pressure and high-temperature environments. The company also noted that brass ball valves were easy to install, operate, and maintain.

Food and Beverage Industry

A case study from a food and beverage processing company demonstrated the versatility of brass ball valves in the industry. The company found that brass ball valves were suitable for a variety of applications, including controlling the flow of liquids, gasses, and solids. The valves were also easy to clean and maintain, making them ideal for use in food and beverage processing plants.

Applications of Brass Ball Valves

Brass ball valves are commonly used in plumbing and heating systems, water treatment and filtration, oil and gas industry, agriculture and irrigation, chemical and pharmaceutical industry, marine industry, and the food and beverage industry. Each of these applications are discussed below.

Plumbing and Heating Systems

In plumbing and heating systems, brass ball valves are used to control the flow of water, steam, and other fluids. They are commonly used in residential and commercial buildings to regulate water flow in HVAC systems, as well as in boilers and other heating systems.

Water Treatment and Filtration Industry

In the water treatment and filtration industry, brass ball valves are used to control the flow of water and other fluids. They are commonly used in water treatment plants, as well as in swimming pools and other water filtration systems.

Oil and Gas Industry

In the oil and gas industry, brass ball valves are used to control the flow of oil and natural gas. They are commonly used in pipelines, refineries, and other industrial applications.

Agriculture and Irrigation Industry

In the agriculture and irrigation industry, brass ball valves are used to control the flow of water and other fluids. They are commonly used in irrigation systems to regulate water flow to crops and other plants.

Chemical and Pharmaceutical Industry

In the chemical and pharmaceutical industry, brass ball valves are used to control the flow of chemicals and other fluids. They are commonly used in chemical processing plants and pharmaceutical manufacturing facilities, where precise control of fluid flow is critical.

Marine Industry

In the marine industry, brass ball valves are commonly used in various applications such as seawater systems, fuel lines, hydraulic systems, and cooling systems. These valves are highly resistant to corrosion and can withstand the harsh saltwater environment. Brass ball valves are also easy to operate and maintain, making them a popular choice for marine applications.

Food and Beverage Industry

In the food and beverage industry, brass ball valves are commonly used for controlling the flow of liquids, gasses, and solids in processing plants. These valves are easy to clean and maintain, making them ideal for use in food and beverage processing plants where hygiene and sanitation are essential. Brass ball valves are also highly resistant to corrosion, which is important in applications where food-grade liquids and chemicals are used.

Choosing the Proper Brass Ball Valve Manufacturer

To ensure you have the most beneficial outcome when purchasing brass ball valves from a brass ball valve manufacturer, it is important to compare several companies using our directory of brass ball valve manufacturers. Each brass ball valve manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each brass ball valve business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple brass ball valve companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services