A valve is a device that controls, regulates, or directs the flow of a fluid, by closing, opening, or partially obstructing one or more passageways. Ball valves are a type of quarter turn valve that controls flow. They serve as more effective alternatives to similar valves, like butterfly valves and gate valves. Review these manufacturer’s overview and click “Request For Quote.”Read More…

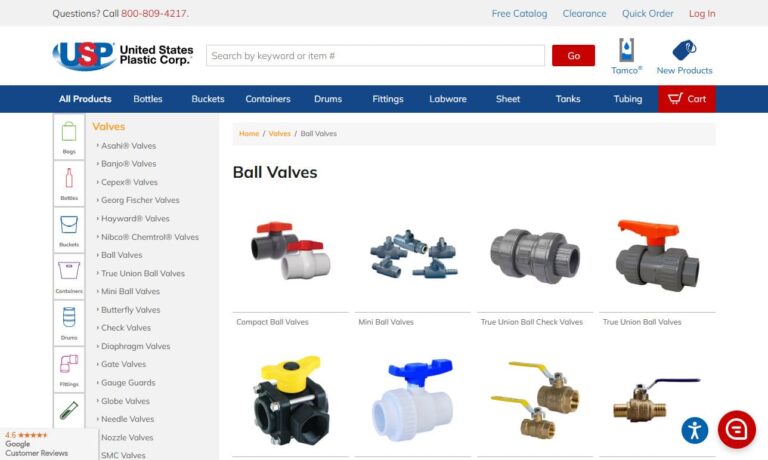

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Valworx offers ball valves in Stainless Steel, Sanitary, Brass and PVC. Our standard quarter-turn ball valves use handles for manual operation. For actuation, some ball valves feature a mounting pad cast into the housing for mounting directly to pneumatic or electric actuators. Actuated ball valve assemblies are typically used for On/Off or modulating control of water, air, oil and other...

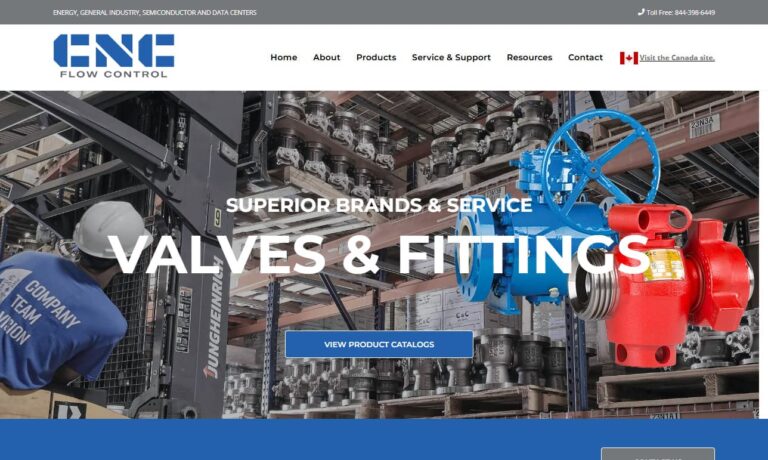

C & C Industries offers high-quality threaded brass ball valves through 4" rated to 600# WOG and carbon steel and ductile iron ball valves through 3" rated up to 5000# WOG. In addition, C & C Industries offers a full line of flanged products in both floating and trunnion design.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Ball Valve Manufacturers

What are Ball Valves Used For? What are their Applications?

Answers:

Key Applications Explained

Ball valves are versatile flow-control devices that use a perforated, pivoting ball to regulate liquids or gases. A quarter-turn of the handle opens or shuts the flow, making them fast, reliable, and durable. Their robust design, ease of operation, and tight sealing capabilities make ball valves the preferred choice across a wide spectrum of industries and critical flow control applications. Wondering where ball valves are most often implemented? Explore the key sectors and use cases below to understand their wide-ranging benefits and industry-specific applications.

Industrial Applications

In oil and gas industries, ball valves play a crucial role in controlling high-pressure pipelines—such as those transporting crude oil or natural gas—thanks to their reliable tight seal, quick shutoff, and corrosion resistance (especially in stainless steel and carbon steel models). Ball valves are commonly found in upstream, midstream, and downstream oil and gas operations, including drilling rigs, refineries, and petrochemical plants. Chemical processing plants leverage ball valves to handle aggressive, caustic, or hazardous chemicals; PTFE (Teflon)-lined valves are particularly effective at resisting acids and solvents at temperatures up to 250°F. In industrial manufacturing, ball valves are used for process isolation, batch control, and fluid transfer operations, supporting applications that require precision and minimal downtime.

Plumbing and Water Systems

For both residential and commercial plumbing, ball valves are essential components in water shutoff and flow regulation, often replacing traditional gate valves due to their leak-proof design and ease of use. Their ability to provide quick shutoff makes them invaluable in emergency situations, such as burst pipes or main water supply interruptions. Municipal water treatment and distribution systems rely on ball valves to control, direct, and isolate flow in filtration, pumping stations, and sewage lines. Sizes for water applications commonly range from ½” to 12”, with larger custom ball valves available for municipal infrastructure.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate coolant, chilled water, or steam in chillers, boilers, and heat exchangers. Their compact size and low maintenance requirements make them suitable for installation in tight or hard-to-reach spaces—such as 1” brass ball valves used to throttle glycol or refrigerants at pressures up to 50 PSI. Ball valves also support zone control in hydronic heating and are frequently specified for their reliability in commercial and industrial HVAC applications.

Food and Beverage

Food and beverage processing relies on sanitary ball valves, typically constructed from 316 stainless steel, for hygienic liquid transfers—handling products such as milk, beer, juices, syrups, and sauces. These valves are designed to meet strict FDA and 3-A Sanitary Standards, with easy-to-clean, crevice-free interiors and tri-clamp connections. Choosing the right sanitary ball valve ensures product purity, prevents contamination, and streamlines cleaning and maintenance operations in breweries, dairies, and food manufacturing plants.

Automotive and Marine

Fuel systems in automobiles, trucks, and marine vessels use ball valves for precise fuel, oil, and coolant flow management. For example, a ¼” stainless steel or brass ball valve on a yacht’s diesel fuel line offers vibration resistance and long-term corrosion protection—even in harsh saltwater environments. Automotive applications may also include ball valves in transmission and emission control systems, supporting both performance and environmental compliance.

Additional Sectors and Custom Applications

Beyond these core industries, ball valves are specified for pharmaceutical manufacturing, pulp and paper processing, mining, power generation, irrigation systems, and fire protection networks. Their use cases include emergency shutoff, process isolation, mixing and diversion, backflow prevention, and pressure relief. Custom-engineered ball valves can be tailored for extreme environments, high purity systems, or specialized flow control tasks.

Why Ball Valves?

With durability (10,000+ cycles), pressure ratings up to 1,000 PSI, and sizes from ⅛” to 48” and beyond, ball valves excel wherever quick, dependable shutoff and reliable flow control are critical—from oil rigs and chemical plants to water treatment facilities and even kitchen sinks. Their adaptability and performance advantages continue to drive their widespread adoption across countless industrial, commercial, and residential applications.

Frequently Asked Questions about Ball Valve Applications

- Which industries benefit most from high-pressure ball valves?

- How do I select the correct ball valve for corrosive chemical handling?

- What size ball valve is best for municipal water main shutoff?

- Are sanitary ball valves required for beverage processing?

- How do floating and trunnion ball valves compare for oil and gas?

- What is the best ball valve for HVAC zone control?

- Can ball valves be automated for remote or IoT-enabled systems?

A Brief History of Ball Valves

In 1871, John Warren patented the earliest known ball-type valve, a brass ball valve design. Although Warren passed the patent to John Chapman, head of Chapman Valves, Chapman opted not to manufacture it, leading to the continued use of older valve designs for many years.

Early valve designs—such as gate and globe valves—dominated fluid control since Roman aqueducts, but they were slow, complex, and prone to leaks. The ball valve, with its simple, quarter-turn shutoff, emerged as a game-changer in flow control technology.

The ball valve concept traces back to the 1930s, when engineers experimented with spherical plugs. A 1936 patent by Harold G. Jones described a rudimentary “ball cock” for water tanks, but the metal-on-metal seats wore out quickly. World War II accelerated innovation: the U.S. Navy required compact, reliable, high-pressure valves for aircraft fuel systems. In 1943, Delta Engineering Company developed a brass ball valve with a floating ball and resilient seats, capable of handling 300 PSI—a crucial starting point for modern designs.

Post-war advancements in sealing materials, most notably PTFE (Teflon), invented by DuPont in 1938 and commercialized by 1947, revolutionized valve performance. By 1954, companies like Jamesbury and Worcester Controls paired Teflon seats with polished steel balls, producing the first leak-tight, high-pressure ball valves. The oil boom of the 1960s drove widespread adoption, as energy infrastructure demanded rapid, rugged shutoff solutions.

The 1970s saw the introduction of stainless steel and trunnion-mounted designs capable of withstanding pressures up to 10,000 PSI, while the 1980s brought sanitary ball valves to the food, beverage, and pharmaceutical sectors. Today, ball valves are manufactured from a wide range of materials—from brass and bronze to titanium and advanced polymers—and are available in sizes from ⅛” for instrumentation to 60” for pipelines. Their evolution from wartime necessity to industrial staple highlights a remarkable history of ingenuity and adaptation.

Ball Valve Designs

Materials

Ball valves can be crafted from a variety of materials, each tailored to specific industry needs and media compatibility. These include bronze, brass, titanium, ductile iron, cast iron, carbon steel, stainless steel, chrome, PTFE (Teflon), PVC, CPVC, polypropylene, and other engineered plastics. Material selection is a critical decision factor, impacting corrosion resistance, strength, weight, cost, and suitability for various fluids or gases.

- Stainless steel ball valves are favored for their high corrosion resistance, strength, and ability to withstand harsh chemicals and high temperatures—making them ideal for oil and gas, chemical, and food processing industries.

- Brass ball valves are valued for their machinability, pressure ratings, and moderate corrosion resistance, often used in plumbing, HVAC, and compressed air systems.

- PVC and CPVC ball valves are lightweight, cost-effective, and highly resistant to water, acids, alkalis, and many industrial chemicals. PVC ball valves are popular in irrigation, pool systems, and chemical handling where metal valves may corrode or scale.

- Carbon steel and ductile iron ball valves are robust choices for high-pressure, heavy-duty applications in oil, gas, and industrial processing.

- Specialty alloys such as titanium or Hastelloy are used for extreme conditions—high purity, aggressive chemicals, or ultra-high temperatures.

Choosing the right material ensures optimal longevity, reliability, and safety in your specific application. Unsure which material fits your system? Request a quote or consultation from leading ball valve manufacturers to discuss your requirements.

Considerations and Customization

When designing or specifying a ball valve, manufacturers and engineers consider a range of application-specific factors to ensure reliable performance and regulatory compliance. These factors include:

- Material of the ball, valve body, and lining (for chemical compatibility and environmental resistance)

- Valve size and port dimension (to match flow rate, pressure drop, and piping layout)

- Pressure and temperature ratings (to withstand system demands and prevent failure)

- End connections (threaded, flanged, welded, or tri-clamp for hygienic service)

- Seal and seat materials (PTFE, graphite, elastomer, or metal seats for different media)

- Actuation method (manual, electric, pneumatic, or hydraulic operation options)

- Certifications and standards (ISO, API, ASME, NSF, or sanitary certifications for industry compliance)

Ball valves are available in a vast array of custom sizes, from miniature valves measuring fractions of an inch for instrumentation panels to massive valves several yards in diameter for municipal water mains or LNG terminals. Customization options include fire-safe designs, anti-static features, extended stems for cryogenic service, and more. For details on tailored solutions, reach out to a manufacturer’s engineering or sales team to discuss your project’s unique requirements.

Features of Ball Valves

Ball valves consist of several critical components:

- Body: The main pressure vessel, housing flow control elements and providing connections for pipe or tubing sections.

- Ball: A hollow, pivoting, and perforated sphere that regulates flow as it rotates.

- Port: The hole bored through the center of the ball, allowing passage of media when aligned with the pipeline.

- Seats: Round disks, usually made of plastic or elastomer, creating a leak-tight seal between the body and the ball.

- Stem: A shaft connected to the ball, enabling its rotation via manual or automated actuation.

- Packing: Flexible seals around the stem to prevent leakage along the shaft.

- Bonnet: A section of the body that houses the packing and stem, often detachable for service.

- Actuator: The operator—lever handle, electric motor, pneumatic actuator, or gear operator—used to open or close the valve.

High-quality design and precision manufacturing of these components ensure reliable performance, minimal leakage, and long-term durability.

Types of Ball Valves

Ball valves are selected and specified based on a range of design features tailored to specific applications and industry requirements. When choosing a ball valve, customers should consider the following primary design configurations and actuation options:

Trunnion ball valves are engineered with advanced mechanisms that secure the ball firmly in a fixed position (supported at both ends by trunnions). This robust design is particularly suited for applications requiring larger valve sizes and the handling of higher pressure levels. Trunnion-mounted ball valves reduce operating torque, accommodate higher differential pressures, and are often used in pipelines, oil and gas transmission, and high-pressure industrial systems. Due to their complexity and superior performance, trunnion ball valves are generally more expensive than their floating counterparts.

Floating ball valves—also known as float ball valves—incorporate a design in which the ball is not anchored but floats downstream into the seat under media pressure. This action creates a tight, reliable seal, making floating ball valves suitable for a variety of standard pressure and moderate-duty applications in chemical, water, and HVAC systems.

Another important factor for customers to consider is the type of valve mechanism:

- Manual ball valves: Operated by lever or handle, providing straightforward, cost-effective shutoff and flow control for most plumbing, irrigation, and industrial service lines.

- Motorized ball valves: Utilize an integrated electric motor to open or close the valve, offering precise control and seamless integration into automated process systems. Ideal for building automation, water management, and remote-controlled industrial processes where manual access is limited.

- Actuated ball valves: Feature an actuator (electric, pneumatic, or hydraulic) mounted on top of the valve, enabling automatic or remote operation. Actuated valves are essential for process automation, batch control, and safety shutdown systems in manufacturing, oil and gas, and power generation sectors.

Specialized ball valve types available include:

- Flanged ball valves: Feature raised flanged edges with bolt holes, providing secure, leak-resistant connections. Flanged ball valves are preferred for high-pressure steam, chemical, water, and oil pipelines, as well as in systems requiring frequent maintenance or valve replacement.

- Multiport ball valves: Available as 3-way or 4-way configurations, these valves manage complex flow patterns by allowing fluid to pass through various outlets. 3-way ball valves, with T or L port arrangements, provide flexibility for mixing, diverting, or distributing flow. Four-way valves, with dual L-shaped ports, offer even greater versatility in process control, making them popular in HVAC, water treatment, and chemical processing systems.

- Non-return ball valves: Also known as ball check valves, these prevent backflow and ensure unidirectional fluid movement, protecting pumps, pipelines, and sensitive process equipment.

- High-pressure ball valves: Engineered to operate efficiently under extreme conditions, these heavy-duty valves withstand pressures up to 7,500 psi or higher. They are vital for hydraulic systems, high-pressure gas transmission, and mission-critical industrial processes where safety and reliability cannot be compromised.

- Globe valves: While distinct from ball valves, globe valves represent an alternative for precise flow regulation, especially in automotive and instrumentation applications. Their disc-and-seat design excels at throttling and fine flow control.

How to Choose the Right Ball Valve Type?

- What are the pros and cons of floating vs. trunnion ball valves for my application?

- Should I select a manual, electric, or pneumatic actuated ball valve for remote operation?

- What are the best ball valve options for high-purity or sanitary process systems?

- How do I specify the correct end connections (threaded, flanged, welded) for my piping?

What are the advantages of using Ball Valves?

Answer: Ball valves stand out in fluid control for their simplicity and high performance. Here’s why ball valves are a top pick for process engineers, facility managers, and system designers across a diverse range of industries:

- Quick Operation: A 90-degree turn fully opens or closes the valve—much faster than gate or globe valves that require multiple twists. This rapid actuation is ideal for shutoff in emergencies, such as isolating a gas line or stopping a chemical leak within seconds.

- Leak-Proof Seal: With a precision-polished ball and resilient seats (often PTFE), ball valves deliver a tight shutoff—achieving zero leakage at pressures up to 1,000 PSI or higher. This makes them ideal for critical containment of oil, water, chemical, and gas media.

- Durability: Engineered from brass, stainless steel, PVC, or advanced alloys, ball valves resist corrosion, abrasion, and wear, often lasting for 10,000–100,000 cycles. A 2” steel valve in a refinery can function reliably for years in harsh service without major maintenance.

- Low Maintenance: Unlike gate or globe valves, ball valves have no internal parts requiring regular greasing. Simple cleaning or a quick seat swap keeps them operational, reducing downtime in HVAC, plumbing, and industrial settings.

- High Pressure and Temperature Range: Trunnion ball valves handle up to 10,000 PSI and temperatures from -40°F to 500°F. Even standard ball valves routinely manage 600 PSI, making them suitable for steam, cryogenic, and high-temperature process lines.

- Versatility: Available in sizes from ⅛” for micro-fluidic systems to 48” or more for mainline pipelines, ball valves handle liquids, gases, slurries, and semi-solids. Specialty designs—like sanitary, fire-safe, or cryogenic ball valves—address unique industry requirements.

- Energy Efficiency: The straight-through, full-port design of ball valves creates minimal pressure drop, enabling pumps to work less and saving power in water treatment, irrigation, and industrial fluid transport.

- Automation Compatibility: Ball valves are easily retrofitted or specified with electric, pneumatic, or hydraulic actuators, supporting integration into automated process controls, IoT-enabled systems, and remote operation networks.

Ball valves blend speed, reliability, and adaptability—outpacing older designs in cost, function, and operational flexibility. Looking for a solution that maximizes flow control efficiency? Consider ball valves for your next project.

Accessories for Ball Valves

Accessories and add-ons for ball valves are essential for maximizing operational efficiency, safety, and ease of use. Below are some common and high-value ball valve accessories and their benefits:

- Handles and Levers: Enable simple manual operation, providing visual indication of open/closed position and quick, intuitive flow control.

- Actuators (Electric, Pneumatic, Hydraulic): Allow for automated and remote control of valve position. Perfect for integration with building management systems, industrial automation, and process control loops.

- Position Indicators and Limit Switches: Offer visual or remote feedback on valve status, supporting system monitoring, diagnostics, and safety interlocks.

- Mounting Brackets and Couplers: Facilitate secure attachment to piping systems, actuators, or support structures, ensuring reliable installation and alignment.

- Stem Extensions: Extend the valve stem for easier access in insulated, buried, or difficult-to-reach locations.

- Protective Covers and Enclosures: Shield valves from harsh environmental conditions, UV exposure, or accidental damage, prolonging service life.

When specifying accessories, always consult the original valve manufacturer or supplier to ensure compatibility and preserve warranty coverage. Many suppliers offer accessory packages tailored to specific valve models and applications. By leveraging their expertise, you can select upgrade options—such as fail-safe actuators, anti-static devices, or lockout kits—that enhance the performance and safety of your fluid control system.

How to Select Ball Valve Accessories?

- Which actuator type (electric, pneumatic, hydraulic) is best for my automation needs?

- Do I need position feedback or remote monitoring for safety compliance?

- What protective covers are available for outdoor or corrosive service?

- Can I retrofit accessories onto existing ball valves?

Proper Care for Ball Valves

Ensuring the longevity and reliable performance of ball valves depends on regular care and maintenance. Proper maintenance reduces the risk of leaks, sticking, or premature failure—especially in mission-critical or safety-related systems. Recommended best practices include:

- Routine Inspections: Inspect valves every 6 to 12 months (or as recommended by the manufacturer) for signs of wear, leakage, or corrosion. Focus on valve body, stem seals, and connection points.

- Lubrication: Apply manufacturer-approved lubricants to the valve stem and seals to reduce friction and prevent corrosion, especially if the valve cycles frequently or operates in harsh environments.

- Exercise the Valve: Fully open and close manually operated ball valves every 3 to 6 months to prevent sticking and dislodge any debris in the ball or seat area.

- Protect from Environmental Exposure: Use protective covers, coatings, or select corrosion-resistant materials for valves exposed to weather, saltwater, chemicals, or extreme temperatures.

- Follow Manufacturer Guidelines: Always adhere to the valve manufacturer’s care, maintenance, and troubleshooting procedures to ensure optimal performance and maintain warranty coverage.

Proper care extends the life of your ball valves, reduces maintenance costs, and ensures reliable system performance. Need a maintenance checklist for your facility? Request industry-specific ball valve maintenance guides from top suppliers.

Standards for Ball Valves

Ball valve design, manufacturing, and application are governed by industry-wide standards to guarantee quality, safety, and compatibility. Major standards organizations include:

- American Petroleum Institute (API): Publishes API 608 and other ball valve standards for oil, gas, and petrochemical service.

- International Organization for Standardization (ISO): ISO 5211 (valve mounting interfaces), ISO 17292 (metal ball valves for industrial use), and others ensure global compatibility.

- American Society of Mechanical Engineers (ASME): ASME B16.34 and related codes specify requirements for pressure/temperature ratings, dimensions, and materials.

- National Sanitation Foundation (NSF) and 3-A Sanitary Standards: Critical for valves used in food, beverage, and potable water applications.

Compliance with these standards ensures valves meet specified pressure ratings, dimensions, materials, and performance criteria, protecting personnel and equipment while supporting process efficiency. When sourcing ball valves for regulated industries (oil and gas, food processing, pharmaceuticals, municipal water), always verify supplier certifications and adherence to relevant standards.

Looking for Ball Valves That Meet API, ISO, or ASME Standards?

- What certifications should I require for valves in my industry?

- How do I verify ball valve compliance with international standards?

- Are there special requirements for food-grade or potable water ball valves?

Choosing the Right Ball Valve Supplier

To achieve the best results when purchasing ball valves—whether for industrial, commercial, or residential applications—leverage our comprehensive directory to compare suppliers based on expertise, capabilities, certifications, and product range. Each supplier’s profile page outlines their core competencies and provides a contact form for direct inquiries or custom quote requests.

Use our proprietary website previewer to quickly assess each company’s specializations, such as high-pressure valves, sanitary ball valves, or automated actuation solutions. For streamlined sourcing, utilize our RFQ form to contact multiple suppliers with the same request, saving time and ensuring you receive competitive quotes tailored to your project’s unique requirements.

When evaluating ball valve suppliers, consider key decision factors:

- Product quality and adherence to industry standards (API, ISO, ASME, NSF, etc.)

- Material and sizing options for your application

- Custom engineering and technical support capabilities

- Availability of accessories, automation, and after-sales service

- Lead times, inventory levels, and global distribution reach

- Certifications, warranty, and reputation for reliability

Ready to compare ball valve options? Browse our full list of ball valve manufacturers or submit your specifications for a fast, customized quote today.

Related Resources and Next Steps

- Explore flanged ball valve options for high-pressure applications

- Learn more about ball check valves for backflow prevention

- Find PVC ball valve manufacturers for chemical and water systems

- Request a quote or technical consultation from top suppliers

Have questions about ball valve selection, sizing, or automation? Contact our experts for personalized guidance and detailed product information tailored to your specific industry and application needs.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services