A spring-loaded or free-floating ball on the sealing seat of a ball check valve closes the valve opening. The chamber is conical in shape, and the seat is machined to fit the ball to seal and stop a reverse flow. If the pump’s capacity is insufficient, A lighter ball can be used, while a heavier ball can prevent water hammer when the pump stops. Since they only need to be maintained if the ball produces noise due to inadequate pump capacity or water hammer, ball check valves are frequently chosen for use in pumping stations that are rarely crewed. In the plumbing business, ball check valves are frequently employed. Read More…

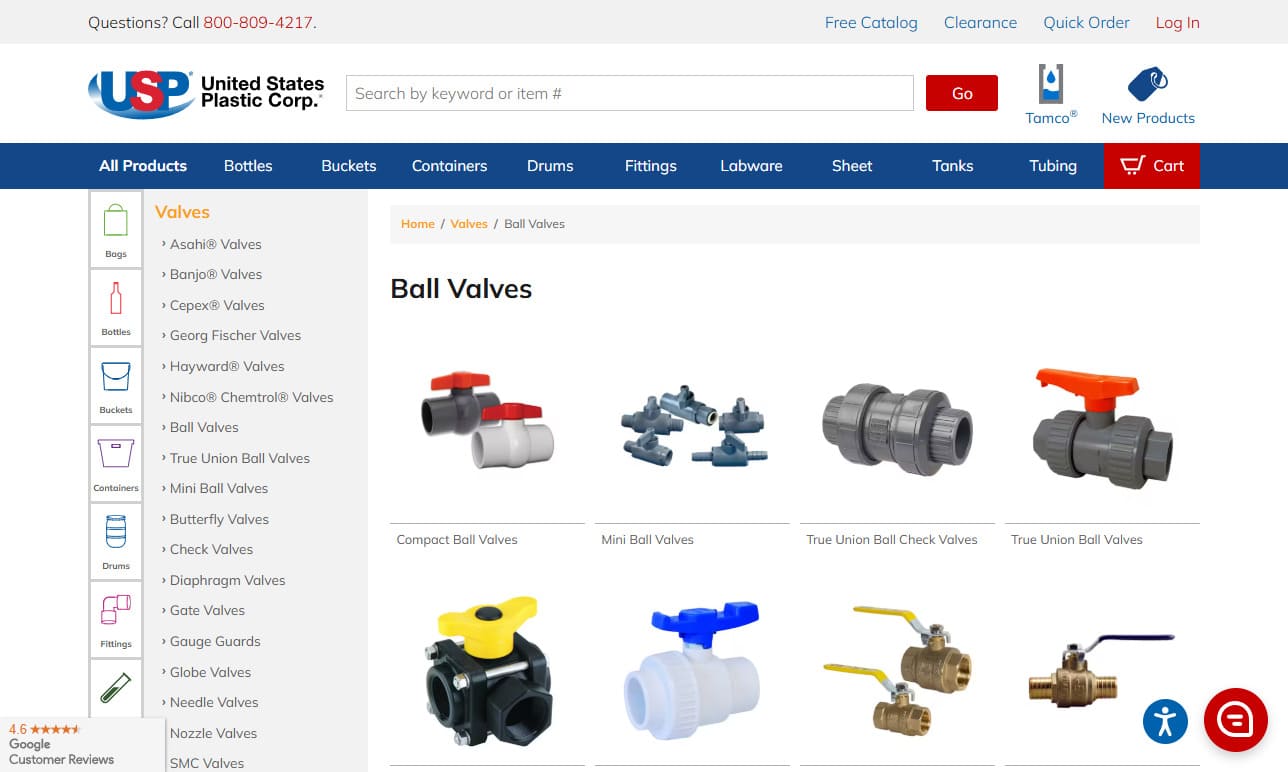

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Valworx offers ball valves in Stainless Steel, Sanitary, Brass and PVC. Our standard quarter-turn ball valves use handles for manual operation. For actuation, some ball valves feature a mounting pad cast into the housing for mounting directly to pneumatic or electric actuators. Actuated ball valve assemblies are typically used for On/Off or modulating control of water, air, oil and other...

C & C Industries offers high-quality threaded brass ball valves through 4" rated to 600# WOG and carbon steel and ductile iron ball valves through 3" rated up to 5000# WOG. In addition, C & C Industries offers a full line of flanged products in both floating and trunnion design.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Ball Check Valve Manufacturers

These valves stop water from running backward through piping systems, sump pumps, and water heaters. Among other materials, PVC, brass, or stainless steel can be used to make ball check valves. The ball inside the valve is normally manufactured from metal. Ball valves typically have specific, low-cost metallic components, while specialty ball check valves are also available. For instance, the ball is made usable in high-pressure pumps in the analytical chemistry industry by using synthetic ruby, a robust and chemically resistant substance.

Working Principle of Ball Check Valves

The basis of the ball check valve's operation is its ability to let flow in one direction while automatically blocking it in the other direction. The control mechanism or disk must open to let the flow from the intake to the outlet due to the liquid pressure.

The disk will automatically seal the channel and stop the reverse flow if the inlet pressure is lower than the outlet pressure. A ball that is either free-floating or spring-loaded and rests on a sealing seat near the intake functions as the control mechanism in ball check valves. The ball rises from its seat and permits the flow when the fluid pressure exceeds the cracking pressure.

How to Install a Ball Check Valve

There are two ways to install check valves technically:

- Ahead of the pump

- Back of the pump

A bottom valve is a device put in front of the water pump and at the vertical suction pipe's end. For this installation to function optimally, The pump should be installed higher than any liquid or water level. The negative pressure technique is another name for it. The valve is placed in front of the pump to fill it with water rather than letting it run dry.

When the liquid level is higher than the pump, the second way of attaching the check valve behind the pump is the best option, and This makes it possible to quickly close and open the water pump without having to close the pump output valve. A ball check valve can be mounted horizontally and vertically in a plumbing system.

- Examine the valve's interior and take out any strange objects you find there.

- Push the ball away from the seating surface to make sure it can move freely.

- Check the valve ends for any raised burrs or edges that could prevent the valve from sealing during operation.

- The flow direction must be up-arrow if the installation is vertical.

- The valve cover must be positioned with the top facing up if it is placed horizontally.

Applications of Ball Check Valves

- They are used in systems for sprinklers and pipes.

- Backflow and the re-entry of possibly polluted water are both prevented using ball check valves.

- Devices like liquid pump dispensers, sprayers, and dispensing syringes all use ball check valves.

- They are used to force plastic forward during the injection molding process and prevent any from sliding backward.

Advantages of Ball Check Valves

Very efficient

Because of the size of the ball's aperture, which contributes to its low-pressure drop and high flow capacity, ball check valves are classified as high recovery valves.

Convenient usage

Ball check valves are effective and convenient due to their straightforward quarter-turn (90-degree) function. In addition, this valve is simple to install and remove because it is lightweight and compact.

Minimal maintenance

Compared to other valve designs, ball check valves are simple to use and require minimal maintenance. In addition, the packing seal on the valve stem does not easily wear out or fail since the ball check valve stem rotates without axial movement.

Cost-efficient

Compared to more complex valve types, ball check valves are less expensive. Additionally, they require less maintenance and are less expensive to maintain.

Durable

Because they can tolerate high pressures, ball check valves are among the most durable valve types.

Disadvantages Of Ball Check Valves

Prone to blockages

Slurries and other viscous liquids tend to harden or clog up inside valve cavities, significantly increasing working torque and, in some situations, making the valve inoperable.

Suffer from long-term throttling

Ball check valves shouldn't be used for long-term throttling and should only be left in fully open or closed positions.

Choosing the Correct Ball Check Valves Supplier

To make sure you have the most beneficial outcome when purchasing Ball Check Valves from a Ball Check Valves Supplier, it is important to compare at least 4 or 5 Companies using our Ball Check Valves directory. Each Ball Check Valves Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Ball Check Valves company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Ball Check Valves companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services